10 Best Resin 3 D Printers For Minis 2025 in the United States

Winner

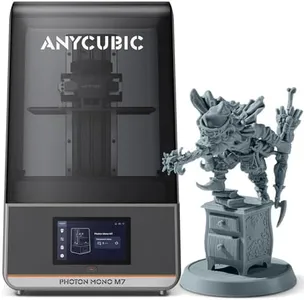

ANYCUBIC Photon Mono M7 Resin 3D Printer, 10.1 inch 14K HD Screen with COB LighTurbo 3.0 System, 150mm/h Fast Printing, Intelligent 3D Resin Printer, Build Volume of 8.77''x4.96''x9.05''

The ANYCUBIC Photon Mono M7 Resin 3D Printer is a solid choice for hobbyists and professionals looking for an efficient option for creating miniatures. One of its standout features is its impressive print speed of up to 150mm/h, which can significantly reduce wait times. Coupled with a high-resolution, 10.1-inch 14K monochrome screen, it delivers detailed models with fine pixel quality, making it suitable for intricate designs.

Most important from

1424 reviews

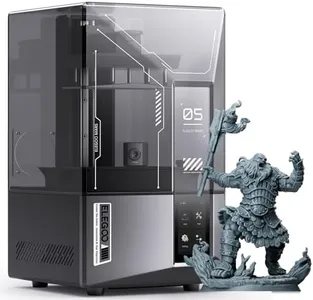

ELEGOO Saturn 3 MSLA 12K 3D Printer, Desktop Resin 3D Printer with 10-Inch Monochrome LCD, Voxeldance Tango Slicer, Large Printing Size of 8.62x4.84x9.84 inches

The ELEGOO Saturn 3 MSLA 12K 3D Printer is a strong contender for anyone looking to create detailed miniatures with resin printing. One of its standout features is the impressive 12K resolution, which allows for incredibly fine details in prints, making it ideal for intricate designs. Coupled with a generous build volume of 8.62x4.84x9.84 inches, users can tackle larger models or multiple pieces in one go, enhancing flexibility for ambitious projects.

Most important from

1292 reviews

ELEGOO Mars 5 Ultra Resin 3D Printer with 7" 9K Mono LCD, 150mm/h High Speed Printing, Smart Automatic Leveling, Intelligent Detection, WiFi-Transfer, Printing Size of 6.04 x 3.06 x 6.49 inch

The ELEGOO Mars 5 Ultra 9K Resin 3D Printer is a standout option for enthusiasts who need high precision and speed for creating miniatures. Its 9K resolution with 18μm XY precision ensures incredibly detailed prints, which is essential for miniatures. The build volume of 6.04 x 3.06 x 6.49 inches is adequate for small to medium-sized models typically seen in minis, providing ample space for detailed creations.

Most important from

1827 reviews

Top 10 Best Resin 3 D Printers For Minis 2025 in the United States

Winner

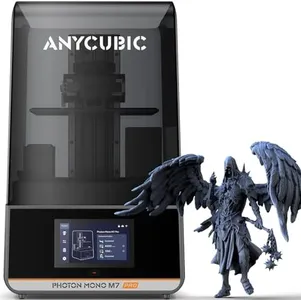

ANYCUBIC Photon Mono M7 Resin 3D Printer, 10.1 inch 14K HD Screen with COB LighTurbo 3.0 System, 150mm/h Fast Printing, Intelligent 3D Resin Printer, Build Volume of 8.77''x4.96''x9.05''

ANYCUBIC Photon Mono M7 Resin 3D Printer, 10.1 inch 14K HD Screen with COB LighTurbo 3.0 System, 150mm/h Fast Printing, Intelligent 3D Resin Printer, Build Volume of 8.77''x4.96''x9.05''

Chosen by 1205 this week

ELEGOO Saturn 3 MSLA 12K 3D Printer, Desktop Resin 3D Printer with 10-Inch Monochrome LCD, Voxeldance Tango Slicer, Large Printing Size of 8.62x4.84x9.84 inches

ELEGOO Saturn 3 MSLA 12K 3D Printer, Desktop Resin 3D Printer with 10-Inch Monochrome LCD, Voxeldance Tango Slicer, Large Printing Size of 8.62x4.84x9.84 inches

ELEGOO Mars 5 Ultra Resin 3D Printer with 7" 9K Mono LCD, 150mm/h High Speed Printing, Smart Automatic Leveling, Intelligent Detection, WiFi-Transfer, Printing Size of 6.04 x 3.06 x 6.49 inch

ELEGOO Mars 5 Ultra Resin 3D Printer with 7" 9K Mono LCD, 150mm/h High Speed Printing, Smart Automatic Leveling, Intelligent Detection, WiFi-Transfer, Printing Size of 6.04 x 3.06 x 6.49 inch

ELEGOO Mars 4 MSLA 3D Printer with 7" 9K Monochrome LCD, UV Resin Photocuring Printer, Multiple Print Modes, Printing Size of 6.04 x 3.06 x 6.89 inches

ELEGOO Mars 4 MSLA 3D Printer with 7" 9K Monochrome LCD, UV Resin Photocuring Printer, Multiple Print Modes, Printing Size of 6.04 x 3.06 x 6.89 inches

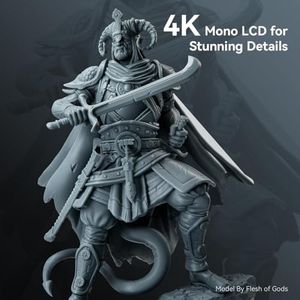

ELEGOO Mars 5 Resin 3D Printer with 4K Mono LCD,Automatic Leveling, Desktop 3D Printer with Printing Size of 5.65 * 3.53 * 5.91 inches

ELEGOO Mars 5 Resin 3D Printer with 4K Mono LCD,Automatic Leveling, Desktop 3D Printer with Printing Size of 5.65 * 3.53 * 5.91 inches

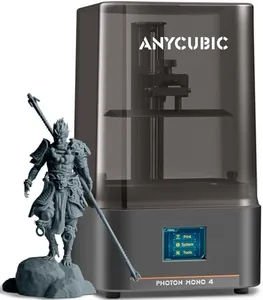

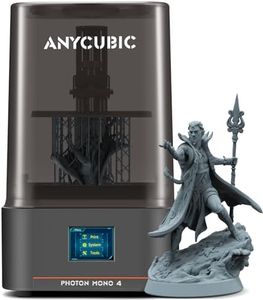

ANYCUBIC 10K Resin 3D Printer, Photon Mono 4 LCD 3D Printer with 7-inch Mono Screen, Upgraded LighTurbo Matrix and Printing Platform, Printing Size of 6.04''x3.42''x6.49''

ANYCUBIC 10K Resin 3D Printer, Photon Mono 4 LCD 3D Printer with 7-inch Mono Screen, Upgraded LighTurbo Matrix and Printing Platform, Printing Size of 6.04''x3.42''x6.49''

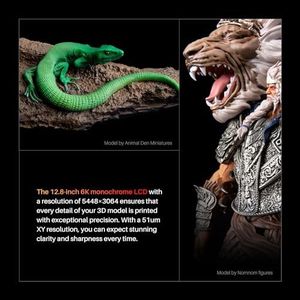

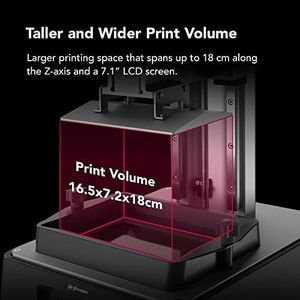

ELEGOO Jupiter SE Resin 3D Printer, Large MSLA 3D Printer with 12.8-inch 6K Monochrome LCD, Printing Size of 10.94 x 6.15 x11.81 Inch

ELEGOO Jupiter SE Resin 3D Printer, Large MSLA 3D Printer with 12.8-inch 6K Monochrome LCD, Printing Size of 10.94 x 6.15 x11.81 Inch

phrozen Sonic Mighty 8K LCD Resin 3D Printer, 10" Monochrome LCD, Tabletop 3D Resin Printer with 28µm XY Resolution, 8.6 * 4.8 * 9.3 Inch Printing Volume for Models, Miniatures and Action Figures

phrozen Sonic Mighty 8K LCD Resin 3D Printer, 10" Monochrome LCD, Tabletop 3D Resin Printer with 28µm XY Resolution, 8.6 * 4.8 * 9.3 Inch Printing Volume for Models, Miniatures and Action Figures

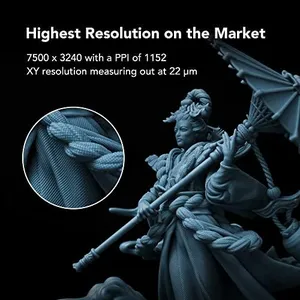

phrozen Sonic Mini 8K S LCD Resin 3D Printer, 7.1" Monochrome LCD, Tabletop 3D Resin Printer with 22µm XY Resolution, 6.5 * 2.8 * 6.7 Inch Printing Volume for Models, Miniatures and Action Figures

phrozen Sonic Mini 8K S LCD Resin 3D Printer, 7.1" Monochrome LCD, Tabletop 3D Resin Printer with 22µm XY Resolution, 6.5 * 2.8 * 6.7 Inch Printing Volume for Models, Miniatures and Action Figures

phrozen Sonic Mini 8K LCD Resin 3D Printer, 7.1" Monochrome LCD, Tabletop 3D Resin Printer with 22µm XY Resolution, 6.5 * 2.8 * 7.1 Inch Printing Volume for Models, Miniatures and Action Figures

phrozen Sonic Mini 8K LCD Resin 3D Printer, 7.1" Monochrome LCD, Tabletop 3D Resin Printer with 22µm XY Resolution, 6.5 * 2.8 * 7.1 Inch Printing Volume for Models, Miniatures and Action Figures

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

![[2024 New] Creality K1C 3D Printer Up to 600mm/s Fast Speed, Reliable Carbon Fiber Printing, Anti-Vibration Design, Auto Calibration for Leveling, Pre-Assembled & Smart OS 3D High Speed Printer](https://images-proxy.bestreviews.guide/fbENyEsi6iLm66n0LUCb5gPo6uI=/0x300/https://m.media-amazon.com/images/I/41D688RqfmL._AC_CX679_.jpg)