10 Best Solder Fume Extractors 2025 in the United States

Winner

KOTTO Solder Smoke Absorber Remover Fume Extractor Smoke Prevention Absorber DIY Working Fan for Soldering Station (Yellow)

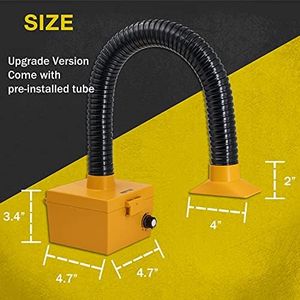

The KOTTO Solder Smoke Absorber is designed for DIY enthusiasts and professionals who want to keep their workspace free from harmful fumes while soldering. With a strong 3000 RPM fan, it effectively removes smoke from a distance of 5-6 inches, which is beneficial for those working in small or confined areas. The activated carbon filter is a standout feature, as it captures fumes from solder and flux, helping to improve air quality.

Most important from

2352 reviews

FumeClear Solder Fume Extractor - Powerful 100W Suction 200m³/h, Low-Noise, 3-Stage Filtration System with 12PCS Filters for Laser Welding Smoke Absorption and Desktop Soldering

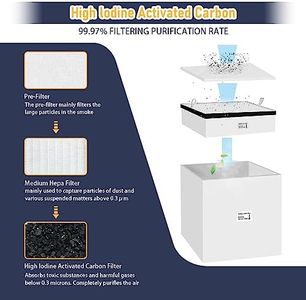

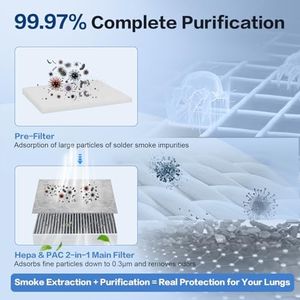

The FumeClear FC100A Solder Fume Extractor is a solid choice for hobbyists and professionals who do small bench soldering. It boasts an impressive airflow capacity of 200m³/h, which means it can effectively remove smoke and contaminants from your workspace. One of its standout features is the 99.97% purification rate, ensuring that harmful particles are filtered out efficiently. This is especially beneficial for maintaining a clean and safe environment for your eyes and lungs.

Most important from

117 reviews

FumeClear FC-2002 Solder Fume Extractor for S1, D1 Pro 10W to 20W Laser Engraver, 260m³/h Strong Suction, Low-Noise with 12 Filters Laser Fume Extractor for Soldering Laser Engraving Smoke Cleaning

The Fumeclear FC-2002 solder fume extractor is a solid choice for those needing clean air while working with laser engraving, desktop soldering, or similar activities. One of its main strengths is its powerful suction capability, which can reach up to 260m³/h, making it effective in capturing various pollutants within a 15cm³ range. This makes it suitable for environments where air quality is a concern, such as small workshops or home settings.

Most important from

22 reviews

Top 10 Best Solder Fume Extractors 2025 in the United States

Winner

KOTTO Solder Smoke Absorber Remover Fume Extractor Smoke Prevention Absorber DIY Working Fan for Soldering Station (Yellow)

KOTTO Solder Smoke Absorber Remover Fume Extractor Smoke Prevention Absorber DIY Working Fan for Soldering Station (Yellow)

Chosen by 1462 this week

FumeClear Solder Fume Extractor - Powerful 100W Suction 200m³/h, Low-Noise, 3-Stage Filtration System with 12PCS Filters for Laser Welding Smoke Absorption and Desktop Soldering

FumeClear Solder Fume Extractor - Powerful 100W Suction 200m³/h, Low-Noise, 3-Stage Filtration System with 12PCS Filters for Laser Welding Smoke Absorption and Desktop Soldering

FumeClear FC-2002 Solder Fume Extractor for S1, D1 Pro 10W to 20W Laser Engraver, 260m³/h Strong Suction, Low-Noise with 12 Filters Laser Fume Extractor for Soldering Laser Engraving Smoke Cleaning

FumeClear FC-2002 Solder Fume Extractor for S1, D1 Pro 10W to 20W Laser Engraver, 260m³/h Strong Suction, Low-Noise with 12 Filters Laser Fume Extractor for Soldering Laser Engraving Smoke Cleaning

Hakko FA430-KIT1 - Two Port Fume Extractor with C1571 Duct Kit with Rectangular Nozzle

Hakko FA430-KIT1 - Two Port Fume Extractor with C1571 Duct Kit with Rectangular Nozzle

FumeClear FC2001A Solder Fume Extractor, 120 to 180m³/h Strong Suction, 3-speed Adjustment, Low Noise High Efficiency Fume Removal, For 110V to 220V Wide Voltage Suitable for Desktop Soldering Iron

FumeClear FC2001A Solder Fume Extractor, 120 to 180m³/h Strong Suction, 3-speed Adjustment, Low Noise High Efficiency Fume Removal, For 110V to 220V Wide Voltage Suitable for Desktop Soldering Iron

YIHUA 948DQ-I Solder Fume Extractor Fan Solder Smoke Absorber Remover Tiltable Angle with 8 Extra Fan Filters for Soldering Wood Burning and more

YIHUA 948DQ-I Solder Fume Extractor Fan Solder Smoke Absorber Remover Tiltable Angle with 8 Extra Fan Filters for Soldering Wood Burning and more

FumeClear FC-2001S Solder Fume Extractor, 128 to 168m³/h Strong Suction, Low Noise High Efficiency 3-speed Smoke Extractor, For 110V to 220V Wide Voltage Suitable for Hand Soldering

FumeClear FC-2001S Solder Fume Extractor, 128 to 168m³/h Strong Suction, Low Noise High Efficiency 3-speed Smoke Extractor, For 110V to 220V Wide Voltage Suitable for Hand Soldering

KOTTO Strong Suction Smoke Absorber for Soldering, Welding, 3D Printing - Extractor with Carbon or HEPA Filter [Updated, Hose Pre-Attached]

KOTTO Strong Suction Smoke Absorber for Soldering, Welding, 3D Printing - Extractor with Carbon or HEPA Filter [Updated, Hose Pre-Attached]

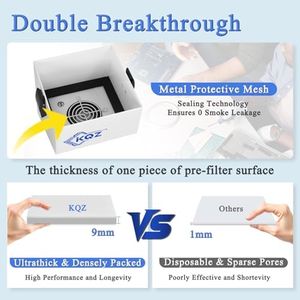

KQZ-W1 Solder Fume Extractor, 168m³/h Strong Suction Smoke Extractor, 5*Thick Pre-Filter+H13 Hepa Soldering Fume Extractor, 99.99% Purification Smoke Absorber for Welding Soldering 3D Printing White

KQZ-W1 Solder Fume Extractor, 168m³/h Strong Suction Smoke Extractor, 5*Thick Pre-Filter+H13 Hepa Soldering Fume Extractor, 99.99% Purification Smoke Absorber for Welding Soldering 3D Printing White

VEVOR Solder Fume Extractor, 150W Soldering Smoke Extractor with 3-Stage Filters, 332 m³/h Strong Suction Smoke Absorber and Purifier for Soldering, Engraving, DIY Welding, Salon, 110V

VEVOR Solder Fume Extractor, 150W Soldering Smoke Extractor with 3-Stage Filters, 332 m³/h Strong Suction Smoke Absorber and Purifier for Soldering, Engraving, DIY Welding, Salon, 110V

Recommended lists

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.